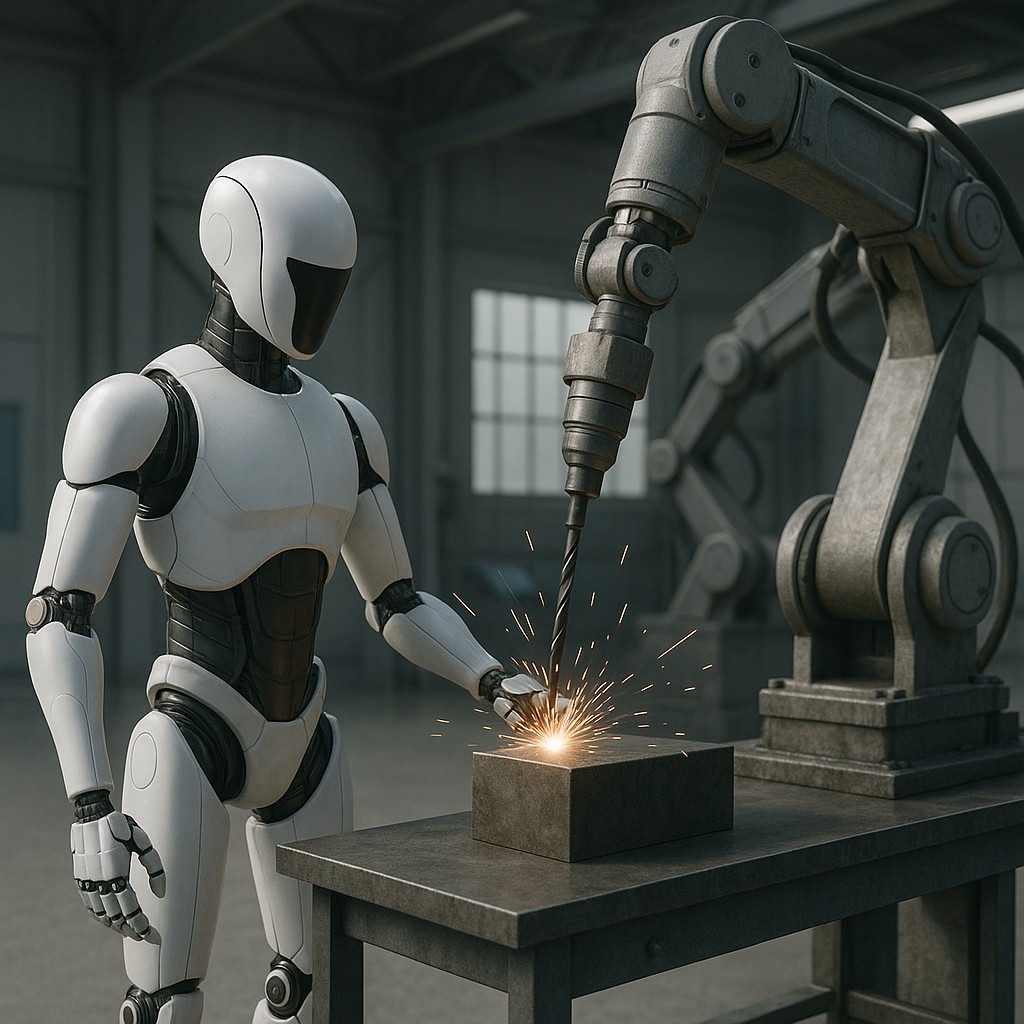

Humanoid robots are finally leaving the lab and entering real-world workspaces. This year, they are transforming how factories operate, performing tasks alongside human workers with surprising agility and efficiency. Companies like Tesla and Boston Dynamics are at the forefront of this movement.

Why Humanoid Robots Are the Future of Factories

Traditionally, industrial robots excelled at repetitive tasks, but they lacked adaptability. Now, humanoid robots—designed to mimic human movement—offer unmatched flexibility. For example, they can climb stairs, open doors, and handle tools with ease. As a result, they fit seamlessly into existing workspaces built for humans.

Furthermore, humanoid robots can switch tasks without major reprogramming, saving valuable time and resources. This versatility is essential for modern factories that handle diverse products and workflows.

Tesla’s Optimus: From Concept to Factory Workhorse

Tesla’s Optimus robot is a prime example of this shift. Initially a futuristic concept, it is now performing tasks autonomously in Tesla’s factories. It takes on “dangerous, repetitive, and boring” work that humans prefer to avoid. Consequently, it improves workplace safety and operational efficiency. According to Tesla’s plans, thousands of Optimus units could be working by the end of this year (robotsguide.com)

Boston Dynamics’ Atlas: Agile and Robust

Meanwhile, Boston Dynamics has unveiled an electric version of its Atlas robot, designed specifically for industrial settings. With exceptional balance and coordination, Atlas can navigate complex environments and handle objects that challenge traditional robots. Thanks to its agility, it can perform tasks like lifting and carrying items, even in tight spaces.

Agility Robotics’ Digit: Filling Labor Gaps

Agility Robotics’ Digit is already operational in warehouses, assisting with tasks like moving boxes onto conveyor belts. Standing at 5-foot-9, Digit is designed to work safely alongside humans, addressing labor shortages in the logistics sector. The company employs a Robot-as-a-Service model, making it accessible for businesses to integrate Digit into their operations (businessinsider.com)

Key Benefits and Challenges

The benefits of humanoid robots are undeniable: they boost productivity, enhance safety, and fill critical labor gaps. Nevertheless, there are challenges to consider. High initial costs, complex technical requirements, and regulatory hurdles can slow adoption. Moreover, some worry about job displacement, although experts argue that robots will complement rather than replace human workers.

Looking Ahead

Clearly, humanoid robots are poised to revolutionize factory floors worldwide. As costs decrease and technology advances, more companies will embrace these machines. In turn, they will gain a competitive edge by increasing productivity and addressing workforce shortages.